Refrigerator thermostat is one of the main components inside the refrigerator . Thermostat is the component that allows the user to set the refrigerator temperature . This is basically a switch that turns off at a set temperature. However , these thermostats can eventually go bad . Bad thermostats can cause non functioning cooling system or always on cooling system .(which can cause refrigerator Ice buildup ) In this tutorial lets look into what cause the refrigerator thermostat not working and how to fix it.

Purpose of a Thermostat

As we have mentioned earlier Thermostat is a switch that breaks the power supply to the cooling system. Thus , preventing over cooling . It switches the compressor and the fan . The main purpose is to allow the user to set the desired temperature inside the refrigerator. The thermostat also have some role in prevention of ice building up inside the refrigerator freezer compartment. Even if you set the thermostat to it’s maximum value the thermostat not going to cause the cooling system to work all the time. Because , The maximum value you can set in the thermostat is decided by the engineers to prevent any over cooling that may cause ice build up that cannot be cope-with the defrost circle.

Working Principle of a Thermostat

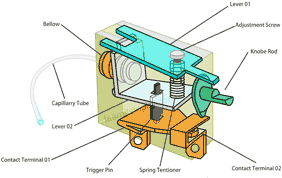

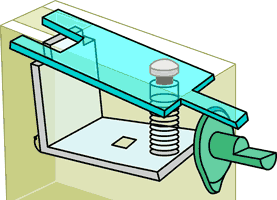

There are mainly two mechanical thermostat types the bi-metal thermostat and capillary tube thermostat . Most common type of thermostat that used in refrigerator is the capillary tube thermostat . Capillary tube thermostat consist of three main parts The Capillary tube system , Mechanical Relay and Mechanical adjusting system.

The Capillary tube system

Thermostat Capillary Tubing and Bellow

It’s a long metal tubing with hole inside .In one end there is a sensing bulb and at the other end is the The capillary bellow (diaphragm) .This tubing is a hollow tubing and it’s confined system filled with freon gas . One side of the tube is crimped (Sensing bulb side) and the other side is open to the bellow . As the tubing exposed to the cold temperature the gas contracts .Causing , bellow to contract .The bellow is pushed by a mechanical system connected to the relay .As the bellow contracts the mechanical components that pushes the bellows also moves towards it. At one point this mechanical system will trigger the relay opening the contacts .Thus , Breaking the circuit (Open circuit).

Mechanical Relay

Mechanical relay is a relay that trigger using mechanical means .The mechanical relay of a thermostat is situated under the thermostat .The contraction of bellow cause the plate that pushes the bellow to move up ward .This upward action release the pressure that put on the relay causing the contacts to be opened . Once the temperature inside freezer increases the bellow will expand pushing the plate other side .This forward action of the plate will put the pressure on the relay causing the relay to make contact .

Mechanical Adjustment system

This system consist of one main dial and hidden adjuster.The main dial rod is fitted with the knob that user can rotate and set temperature. The hidden adjuster is a screw adjuster that set the tension of the spring that pushes the plate towards the bellow .If you rotate the screw adjuster anti-clockwise you can increase the tension of the spring .Thus , Increasing the value of the main dial can reach (Setting the maximum). If you rotate the screw clockwise you can reduce the tension of the spring .Resulting , lowering of the value of the main dial can reach .This same assembly is used for for pushing the relay trigger .

Electronic Thermostat Regulator

Refrigerator Controller circuit board

Modern refrigerators don’t have these mechanical thermostat regulators . If you look what is behind a modern refrigerator’s regulator knob, You will find out that there is not much components .You will see a single potentiometer . This potentiometer is connected to the Main controller board . A Temperature sensor provides the temperature readings inside the freezer to the microcontroller in the controller board . The set temperature (Potentiometer position) will be calculated via analog to digital converter inside the microcontroller . As the set temperature reached , The microcontroller will turn off the cooling by turning off the compressor .

Refrigerator Thermostat Not working Fix – Mechanical Regulator

There are are several things that can cause defrost timer malfunction . However ,These things can be fixed easily .Here are some of the causes of refrigerator thermostat not working and how to fix them.

Rust

Checking the motor coil

Rust is very common cause where metal and moisture present .There are many moving metal parts inside a thermostat . Rusting can cause stuck and broken parts which will cause the malfunction of the thermostat regulator .

fix – If you can see any rust use a sand paper or wire brush to remove the rust and If there any damaged parts due to rust . Try to replace the part .Then , Apply some grease on the moving mechanical parts.

Damaged Capillary System

Simple puncher in the capillary tubing and bellow can cause the refrigerant gas to be relisted to outside. That’s why you should be careful when handling the capillary tubing . It can lost it’s seal anytime specially at the place where capillary tube and bellow connects .

Testing – you can test if the capillary system is good or bad by measuring the movement of the bellow .You don’t have to take apart the thermostat. Look at the top of the thermostat you will see a metal part (dial) inside a rectangular shaped cutout. It moves as the bellow contracts and expands.Look at the position of that dial at room temperature .Then , Put the capillary tube inside a glass filled with ice cubes . See whether the dial moves or not (results may take some time ) . If you cant see any movement in the dial you have either bad capillary system or a mechanical problem

Fix – If the capillary tubing goes bad there is little or less you can do .It require special equipment to fill and fix the puncher .

Bad relay Contacts

Sanding contact points of defrost timer

As the relay trigger pushes and retracts the contacts made and breaks. As the contacts touches each other sparks can appear these sparks appear due to the current flow through two contact points . These sparks can cause the contact points to be damaged. If contact points are damaged and deformed the contacts are not properly made .Thus, No current flow. This is one of the main causes of refrigerator thermostat not working.

Fix – Use a fine sand paper (600P -1000P) and sand it down to it’s proper shape to make sure proper contacts made between each contact points .

Oxidation

Cleaning oxidized metal parts

If you are living in a coastal area ,you know that oxidization is a big problem in day-today life. These oxidization can effect any metal part inside the defrost timer .

Fix – Take apart the defrost timer. Use a toothbrush dipped in a isopropyl alcohol . Then , Brush any metal part inside. You can also use a contact cleaner and spray to the metal contacts inside the defrost timer.

Refrigerator Thermostat Not working Fix – Electronic Regulator

There are are several components need to be checked if your Electronic thermostat regulator doesn’t work . Here are some of the and how to fix them.

Bad Potentiometer

Most of the time it’s the mechanical parts that go bad . If you spin the regulator knob all the time , It will cause the restrictive plate inside the potentiometer to wear fast . Resulting bad regulator position readings . Thus , microcontroller will not be able to regulate the temperature at set temperature.

Fix – Put the multimeter in Ohm scale and touch one pin at the edge with one probe and the center pin with the other probe . Check if the resistance changes as you rotate the axle of the potentimeter. Check whether it changes from zero ohms to the value mentioned in the potentiometer (approximately). Do the same to the other pin too. If you get any unusual readings , Replace the potentiometer.

Bad Wires

Refrigerator damaged wire

Some times bad damaged wires can cause the electronic thermostat regulator malfunction .Rats or other animals can damage these wires that goes to the controller board . As wires gets old they become brittle and can easily get damaged or short circuit .

Fix – Put your multimeter in buzzer mode (continuity mode) and touch each pin of potentiometer and temperature sensor while touching the related solder points of the wire ends in the controller board . If the buzzer beeps , It means the wires are good . But , If the buzzer doesn’t beep ,It means bad connectivity or bad wires . The bad wires need to be replaced .

Dry Solder

Dry or cold solder joints in a PCB

Have you ever seen solder points with circle around it . That is called dry solder point or cold solder joints . As refrigerator works it vibrates due to the compressor , This have impact on the solder points .They also gets separated from the PCB due to this vibration. Most of the time this is visible to eyes (See the image).

Fix – Look at the back side of any PCB inside the refrigerator and look for dry solder points . Then , Re-solder them .

Bad Temperature sensor

Refrigerator Temperature sensor

Temperature sensors can go bad due to many reasons . Voltage spikes , Heat , corrosion and shorted circuits are some of them . There are two types of sensors . Digital sensors and Analog sensors .Analog sensors can be checked with a multimeter .But , Digital sensors require microcontroller to test them .

Fix – In order to check them you need to read the datasheet of the component . Google search the part number and download the datasheet pdf file .Check whether the required minimum voltages are available at the sensor pins using a multimeter . There will be testing circuit diagrams in the datasheet , You may have to create such circuit to check whether it properly works or not.

Conclusion

Capillary tube thermostats can go bad due to various reasons. Mechanical thermostat regulators can be easily repaired .In the other hand electronic thermostat regulators are hard to repair.It requires good knowledge in electronic equipment repair . Although , some repairs require special tools most repairs doesn’t require such knowledge or tools. You should be careful when handling capillary tube .It can be easily damaged .

Frequently Asked Questions

How to replace the thermostat regulator ?

If you are talking about replacing a mechanical thermostat . You can look for the replacement part with the part number of the thermostat regulator. But , If you cant find a exact match , You can replace it with a matching mechanical thermostat regulator. However , Make sure to match current , voltage and temperature ratings with the OEM part . After replacing the old one with a new one you may need to set the relay trigger temperature using the screw above the mechanical thermostat regulator.

How to Know If the thermostat is bad ?

If your refrigerator doesn’t get cold as it used to be , Most likely cause can be the bad a thermostat regulator . But , Make sure that other components are working properly .Before replacing your thermostat regulator.

How to replace the Electronic thermostat ?

As we have mentioned in the tutorial , Electronic thermostat regulator is not a single package device .You can replace the temperature sensor and regulator potentiometer. If replacement of those components doesn’t fix your issue , You may have to replace the controller IC or the main controller board .

Disclaimer – The contents of this article may change anytime.This tutorial involves working with high voltages . In order to work with such voltages , It requires special tools and protective equipment. Make sure to take every safety measure necessary . If you don’t have any experience working with high voltages .Please , Get someones (Someone who have experience ) help to follow this tutorial.If you are not a experienced technician , Don’t work on the refrigerator while it is connected to the mains.